- 2010 Unit in very good condition

- Few Hours

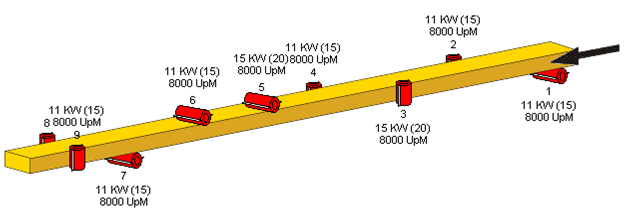

- 9 heads

- Located in Canada

Specifications:

1st head - Bottom - 40mm spindle - 11kw

8000 rpm

Electronic digital display for radial adjustment MarathonCoating - Table plates

2nd head - Right - 40mm Spindle - 11kw

8000 rpm

3rd Head - Left - Powerlock spindle - 15kw

8000 rpm

Pressure pad in front of the left tool holder, incl. 2 lateral Pressure rollers, pneumatic.

Vario hood (2 axes)

Central adjustment of the pressure and guide elements before and after the tool holder incl. electronic digital display.

4th head - Right - Powerlock - 11kw

8000 RPM

5th head - Top - Powerlock - 15kw

8000 RPM

Vario hood (2 axes) Central adjustment of the pressure and guide elements before and after the tool holder incl. electronic digital display.

Slotted pressure shoe in front of the upper tool holder, pneumatic

Oscillating axial adjustment

6th head - Top - Powerlock - 11kw

8000 RPM

Vario hood (2 axes) Central adjustment of the pressure and guide elements before and after the tool holder incl. electronic digital display

Slotted pressure shoe in front of the upper tool holder, pneumatic

Oscillating axial adjustment

7th head - Bottom - Powerlock - 11kw

8000 RPM

8th head - Right - Powerlock - 11kw

8000 RPM

An additional pressure roller from the opposite top right 3rd

Tool holder, swivel for easy tool change, pneumatic

9th head - Left - Powerlock - 11kw

8000 RPM

Vario hood (2 axes) Central pressure adjustment and front and rear left guide elements

Tool holder incl.

Electronic digital display. Frequency controlled advance, 11 KW (feed table 6.66 m / min 2.5 meters)

Automatic lubrication pump Two rollers driven in the machine table, hardened

Top pressure rollers, pneumatic PowerCom Plus software CNC controlled adjustment and positioning.

Axial CNC - controlled adjustment and positioning of tool holders in conjunction with memory or PowerCom function.

For tool holder no. 2,3,4,5,6,7

Radial adjustment and CNC control of tool holders in combination with memory or PowerCom function.

For tool holder n ° 3,4,5,6,7

CNC controlled adjustment and feed positioning Automatic central lubrication of oscillating tool holders

Two interior lights in the safety hood