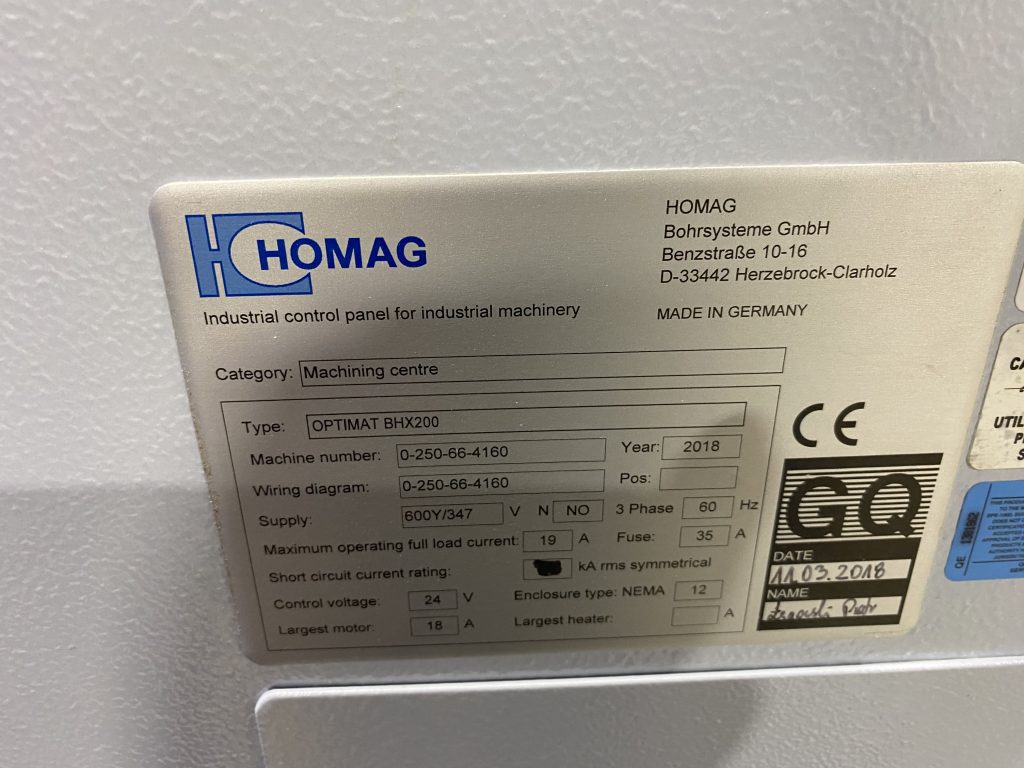

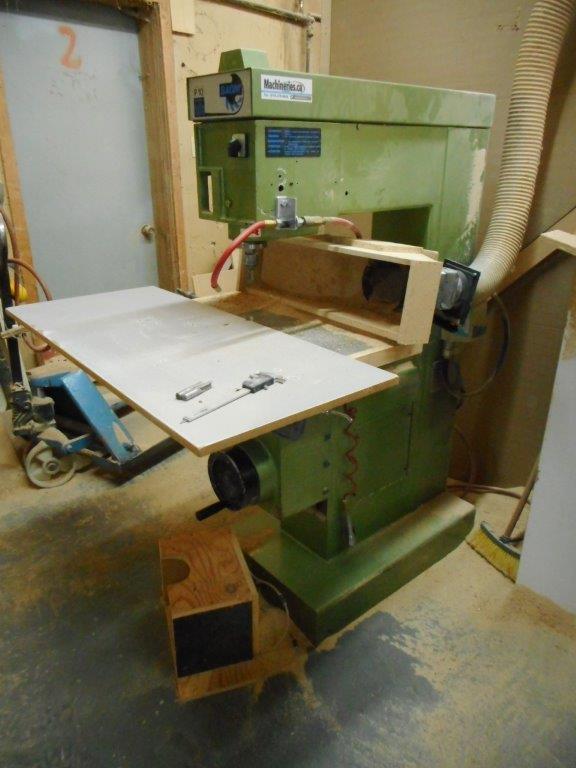

Flexible "vertical" machining center with "ATC" that uses less than 5 square meters of valuable floor space in addition to an innovative panel handling system.

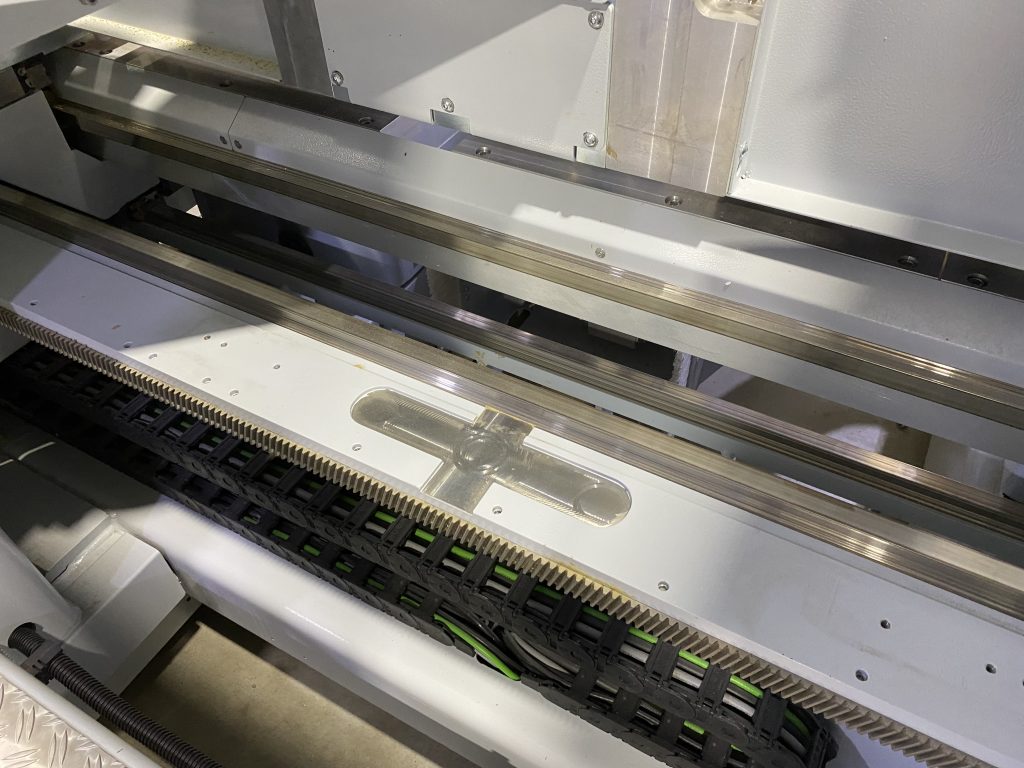

Max. usable workpiece size for "X" axis is 120" (3050mm), "Y" axis is 49.2" (1250mm) and max. piece thickness 3.1" (80 mm).

Min. worktable part size for "X" axis is 7.8" (200mm), "Y" axis 2" (50mm), min. 0.31" (8mm) workpiece thickness. Automatic left or right side feed and exit.

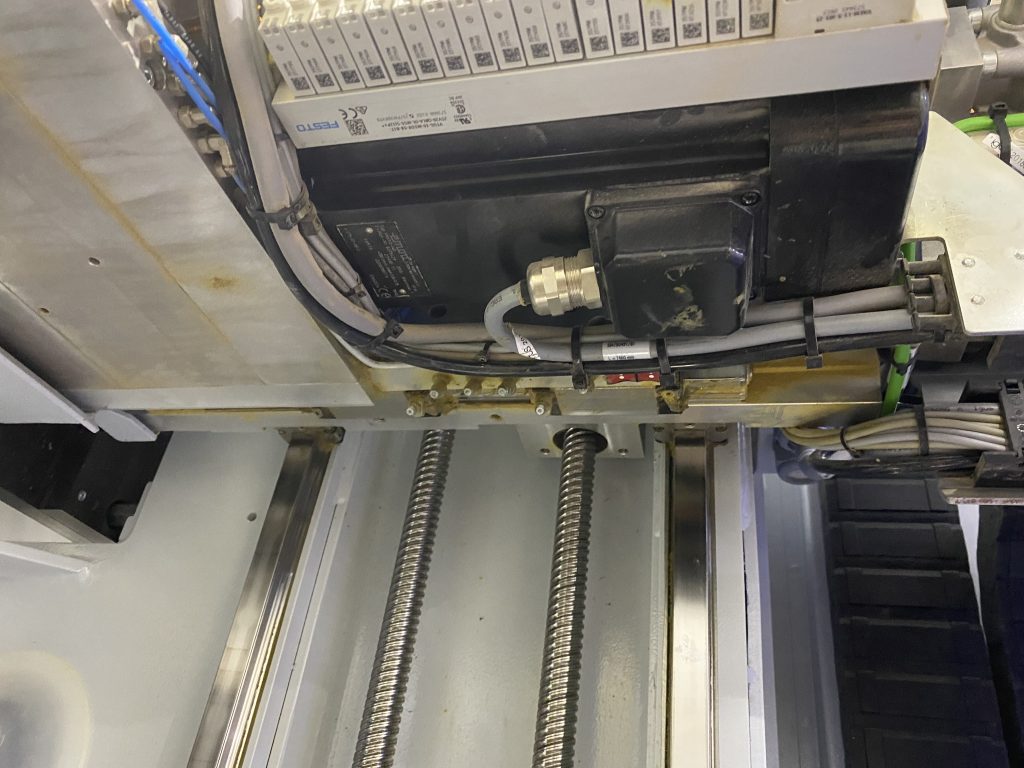

The BHX 200 can reach travel speeds of 164 FPM (50 MPM) in the "X" and "Y" axes and 50 FPM (15 MPM) in the "Z" axis in complete safety, providing unparalleled work capacity .

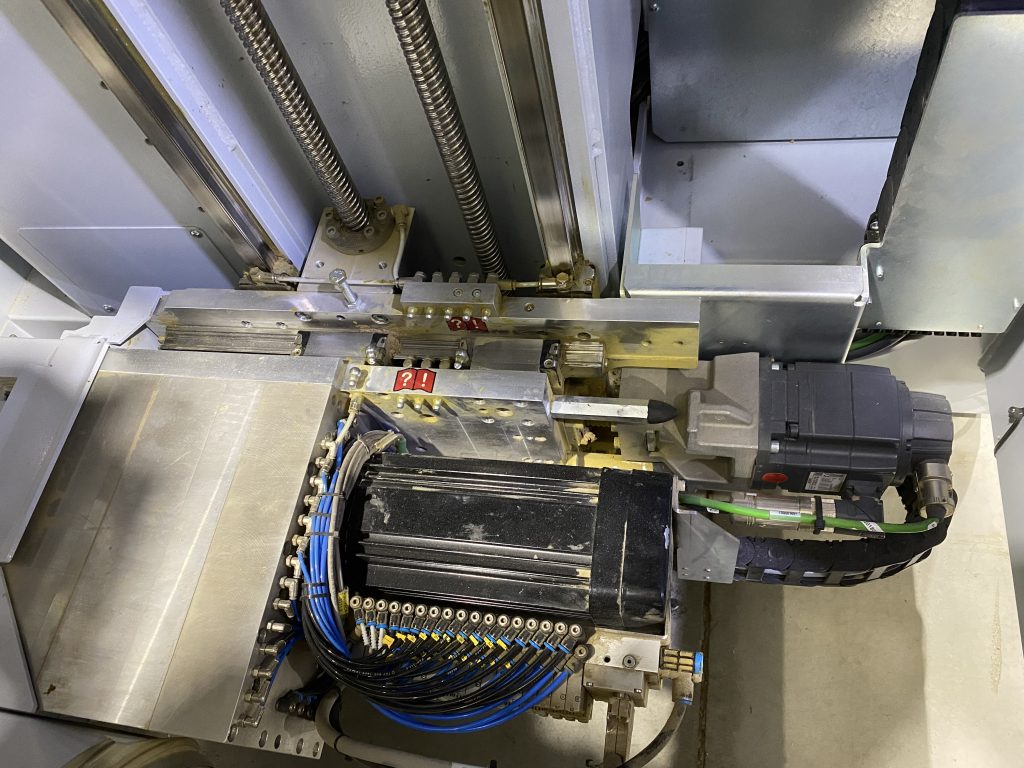

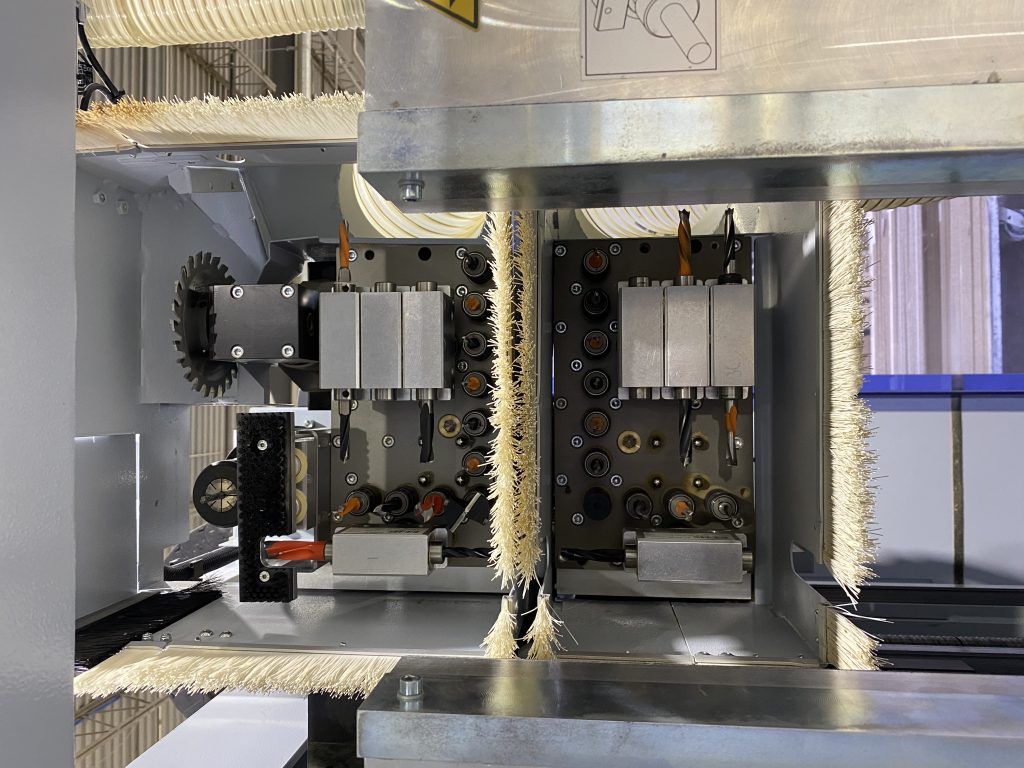

(1) 3 HP (2.3 kW), 1500-7500 RPM variable speed motor, (20) independent spindles with (14) spindles on "X" axis and (6) spindles on L "Y" axis.

(16) Horizontal spindles with (6+6) in "X" axis and (2+2) in "Y" axis; The boring block has a "QUICK CHANGE" spindle system.

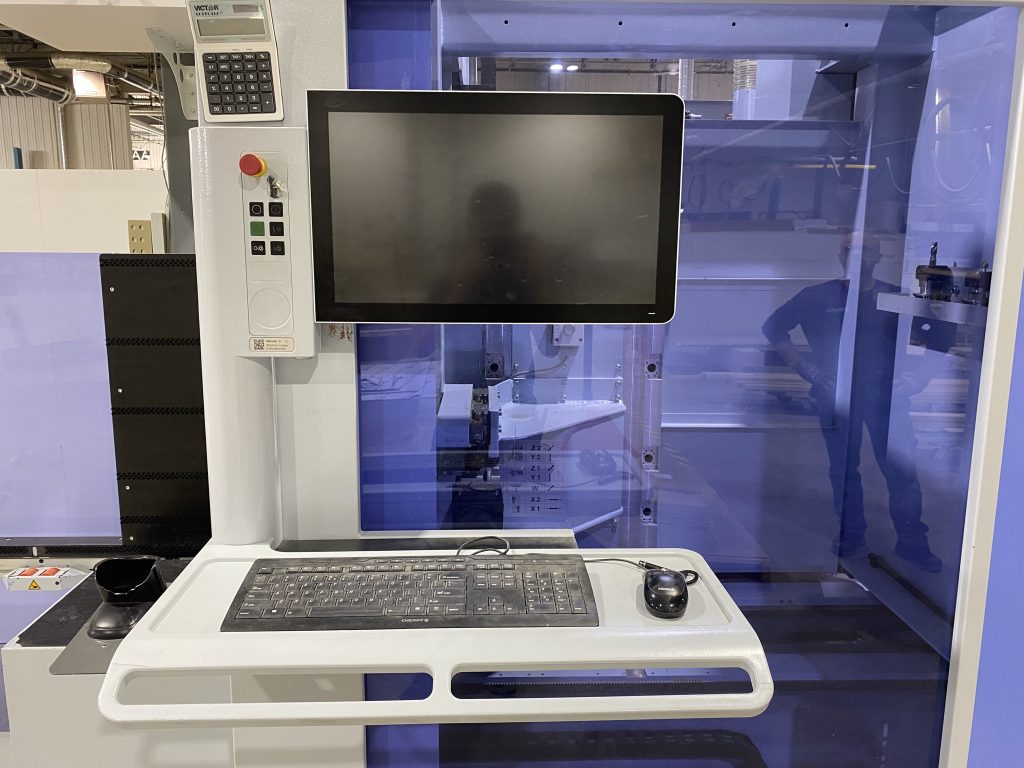

Weeke "POWERTOUCH" + Windows + WoodWOP 6.1 + operating system; "IntelCore 2 DUO" processor.

17 inch TFT monitor; international keyboard, touch keyboard and industrial mouse; RS-232 serial ports, USB ports; (1) 1.44 MB floppy drive, (1) CD RW drive, modem, Ethernet connection.

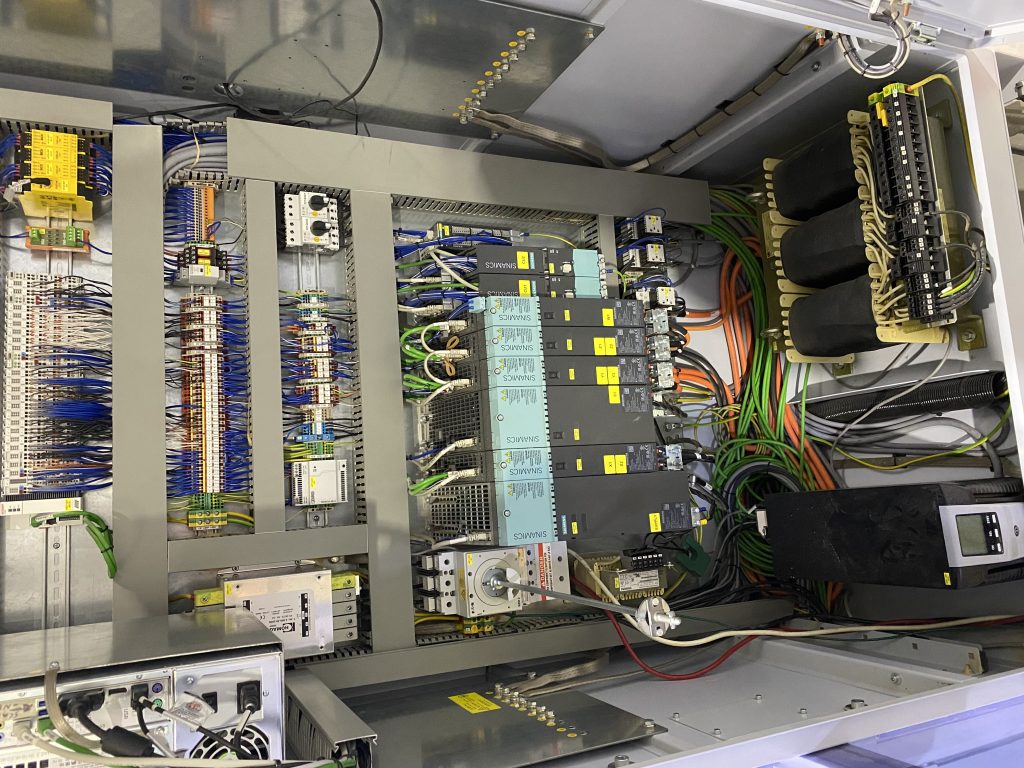

Pneumatic workpiece clamping devices; soundproof enclosure and complete set of safety devices.

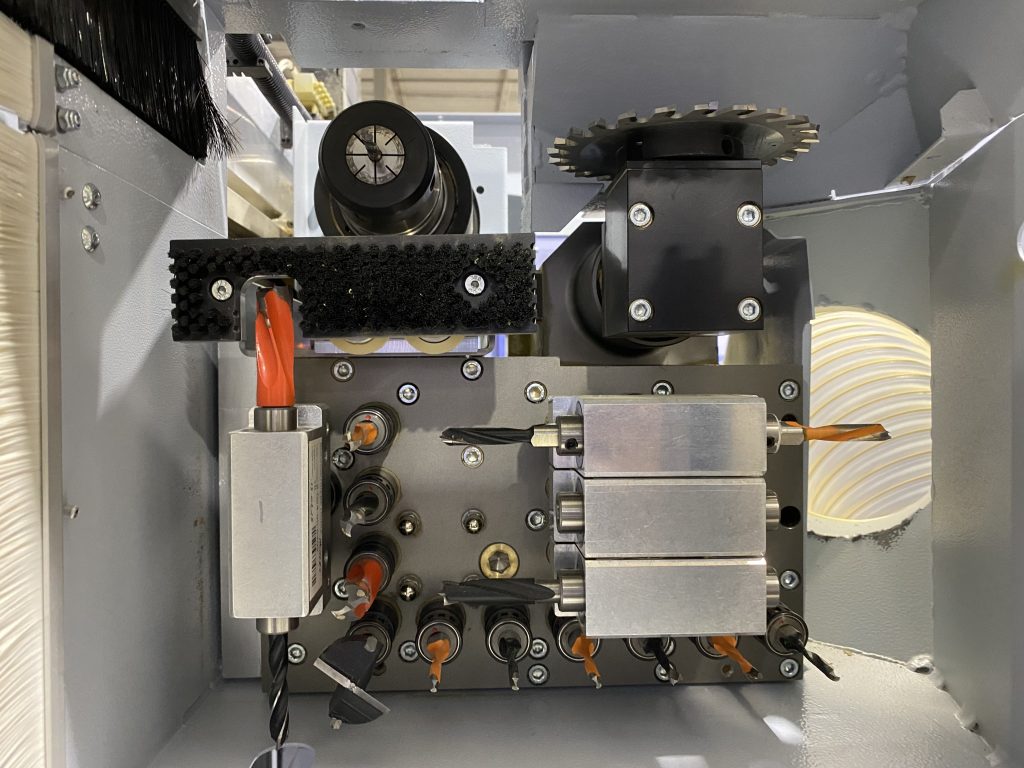

(1) 12 HP (9 kW) electrospindle spindle moulder with HSK F3 adaptor, variable speed from 6,000 to 24,000 rpm.

(1) 4 position ATC tool post mounted on the side of the machine base.

Dimensions Valued : 144" x 96" x 90" Like new Turnkey option with certified technician.

The information provided for lr CNC has been gathered from the literature, it is believed to be accurate. Buyers will be able to validate the information during the private visit to inspect and verify the CNC.

Flexible "Vertical" Machining Center with "ATC" that uses less than 5 meter² of valuable floor space in addition to an innovative panel handling system.

Max. workable part size for "X" axis is 120" (3,050 mm), "Y" axis 49.2" (1,250 mm), and max. part thickness 3.1" (80 mm).

Min. worktable part size for "X" axis is 7.8" (200 mm), "Y" axis 2" (50 mm), min. part thickness of 0.31" (8 mm). Automatic infeed & outfeed from the LH or RH side.

The BHX 200 can reach movement speeds of 164 FPM (50 MPM) in "X" & "Y" axis & 50 FPM (15 MPM) in "Z" axis with total safety, providing an unmatched working capacity.

(1) 3 HP (2.3 kW), variable speed from 1,500 - 7,500 RPM motor, (20) independent spindles with (14) spindles in "X" axis & (6) spindles in "Y" axis.

(16) Horizontal spindles with (6+6) in "X" axis & (2+2) in "Y" axis; Boring block has "QUICK CHANGE" spindle system.

Weeke "POWERTOUCH" + Windows + WoodWOP 6.1 + operating system; "IntelCore 2 DUO" Processor.

17" TFT Monitor; international keyboard, soft-touch keypad & industrial mouse; RS-232 Serial ports, USB ports; (1) 1.44 MB floppy disk drive, (1) CD RW drive, moden, Ethernet connection.

Pneumatic part clamping devices; sound enclosure and complete set of safety devices.

(1) 12 HP (9 kW) Electro spindle router with HSK F3 adapter, variable speed from 6,000 - 24,000 RPM.

(1) 4-position ATC tool rack mounted on the side of the machine base.