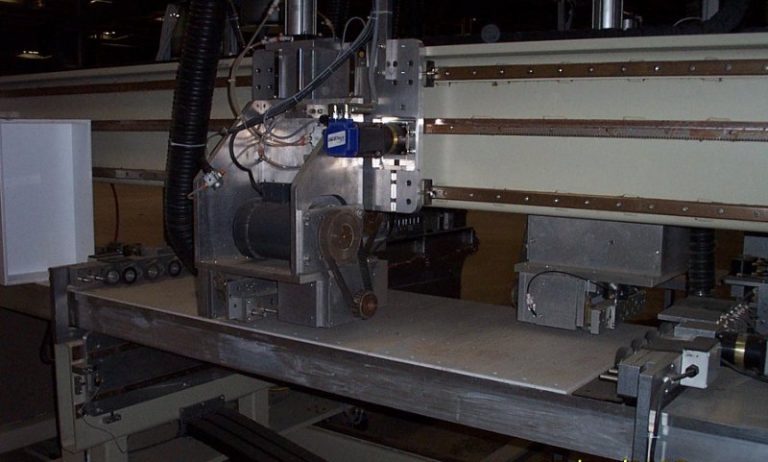

BIESSE TECHNO LOGIC

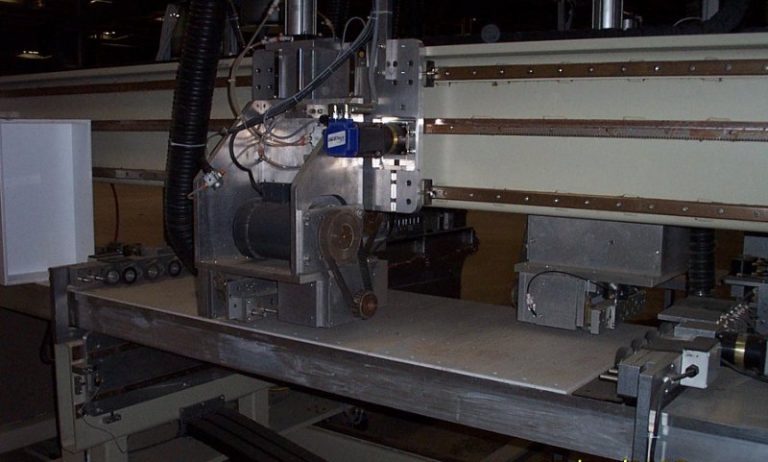

AUTOMATIC IGNITION DRILL MACHINE

GENERAL SPECIFICATIONS

- Panel drilling: - horizontal - bottom vertical - top vertical

- Working area in the "X" axis: 3200mm

- Minimum distance from center of "X" axis between vertical units 96mm

PANEL HANDLING SYSTEM AND OPTIONS

- 2 belt conveyors, 1 fixed and 1 adjustable according to the working width - 0.25 HP motors

- Continuous speed adjustment of belt conveyors powered by automatic regulation by control panel

- 6 pressure units

- Automatic regulation of backstop measurements by control panel

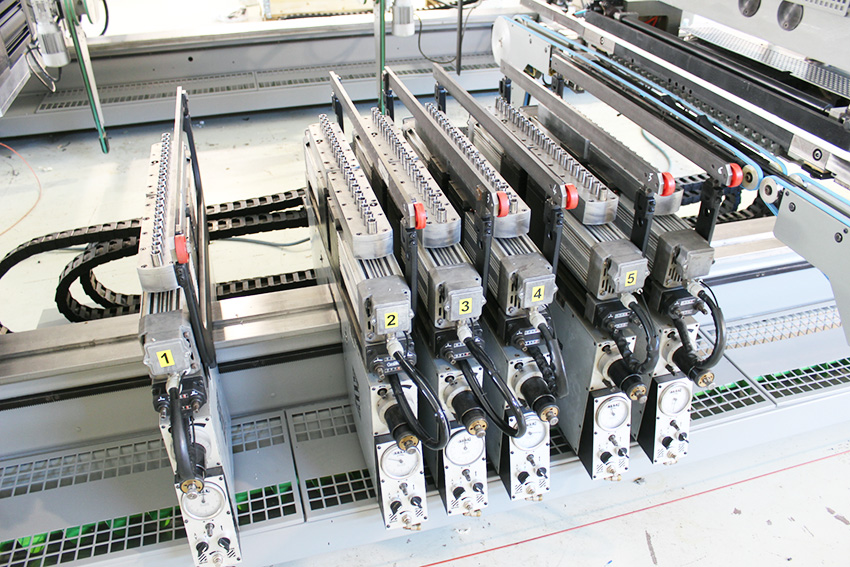

BORING UNITS

- 6 lower vertical units

- 4 top vertical units

- Various number of spindles for vertical drill heads

- 2 (1 + 1) horizontal drill heads

- 20 spindles for horizontal drill heads

- Motor power of work units 1.8HP (3600 rpm)

- Hand regulation with the visual unit of the position of the "Y" axis of the drilling heads on the vertical units

- Hand regulation with the visual unit of the position of the "X" axis of the vertical units

- Hand regulation with visual unit of the "Z" axis of the drilling depth

- Automatic regulation by digital control of the "X" axis position of the mobile horizontal unit

MACHINE CONTROL AND ACCESSORIES

- CNI RT 483 control and programming system with the following features: visual display, keyboard

- Control panel installed on a built-in electrical cabinet to control the machine

STANDARDS AND OPTIONALS FOR SAFETY

- Safety standard CE mark

- Automatic system to eliminate wood waste

- Total installed power 54KW

*****************

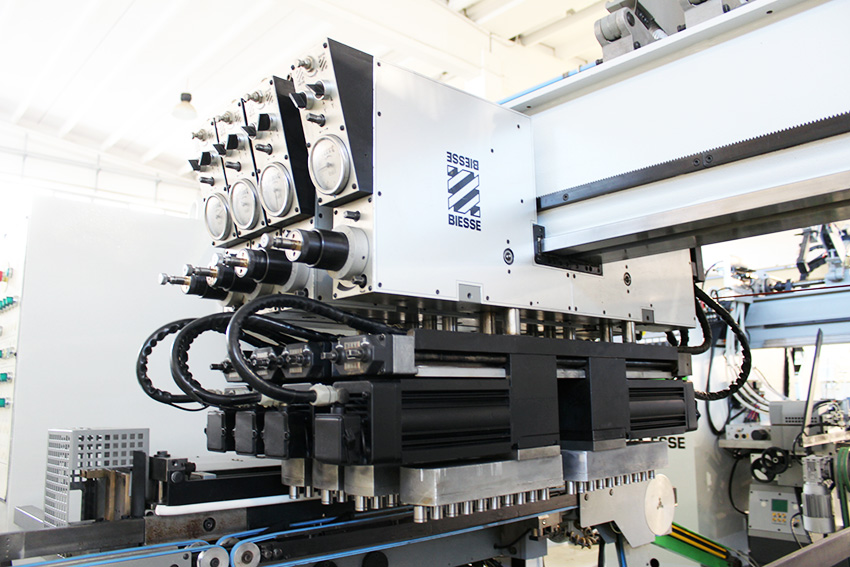

BIESSE TECHNO SDT

AUTOMATIC INSERTION MACHINE WITH FOOD PROCESSING AND DOWEL

GENERAL SPECIFICATIONS

- Industrial and fast machine

- Panel drilling: vertical bottom

- Working area in the "X" axis: 3200mm

- Distance from center of "X" axis between vertical units 96 mm

PANEL HANDLING SYSTEM AND OPTIONS

- 2 belt conveyors, 1 fixed and 1 adjustable according to the working width - 0.25 HP motors

- Continuous speed adjustment of belt conveyors powered by automatic regulation by control panel

- 4 pressure units with automatic "X" axis position regulation by digital control

- Automatic regulation of backstop measurements by control panel

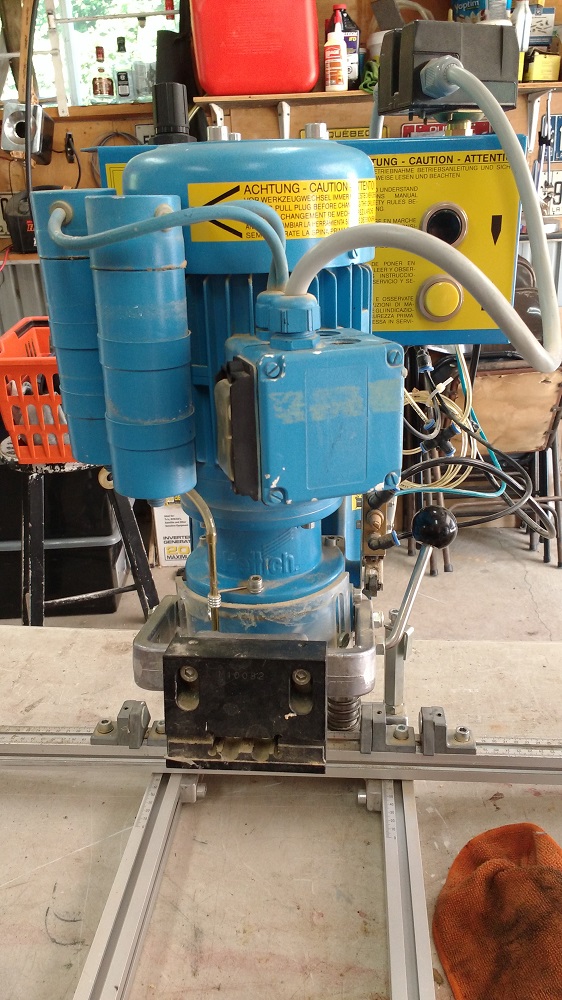

BORING UNITS

- 3 lower vertical units

- Various number of spindles for vertical drill heads

- Drillhead "quick change" system

- Motor power of work units 1.8 HP

- Hand regulation with the visual unit of the position of the "Y" axis of the drilling heads on the vertical units

- Automatic regulation by digital control of the position of the "Y" axis of the drilling heads on the vertical units

- Automatic regulation by digital control of the "X" axis position of the vertical units

- Automatic regulation by digital control of the "Z" axis of the drilling depth

- Automatic regulation by digital control of the "X" axis position of the mobile horizontal unit

- Numerical displays which indicate: - Position of the "X" axis of the vertical units - The "Y1-Y2" axes position the drilling head of the vertical units - Position of the "X" axis of the mobile horizontal unit - transmission from the digital measurement control To easily configure the positioning of the axes of the work units.

DOWEL INSERTING UNITS

- 5 anchor insertion units for each side with start from the control panel

- High pressure glue injection system

- 2 reservoirs to store the ankles with vibration system

MACHINE CONTROL AND ACCESSORIES

- NC 500 control and program system with the following functions: -PC - color display - CD-ROM drive - keyboard

- Control panel installed on a separate electrical cabinet to control the machine

STANDARDS AND OPTIONALS FOR SAFETY

- CE safety standard

- Safety photoelectric cells

- Automatic system to eliminate wood waste