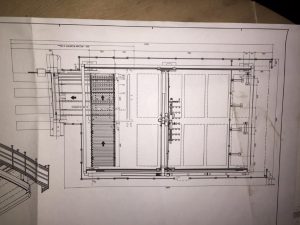

Working height: 950mm

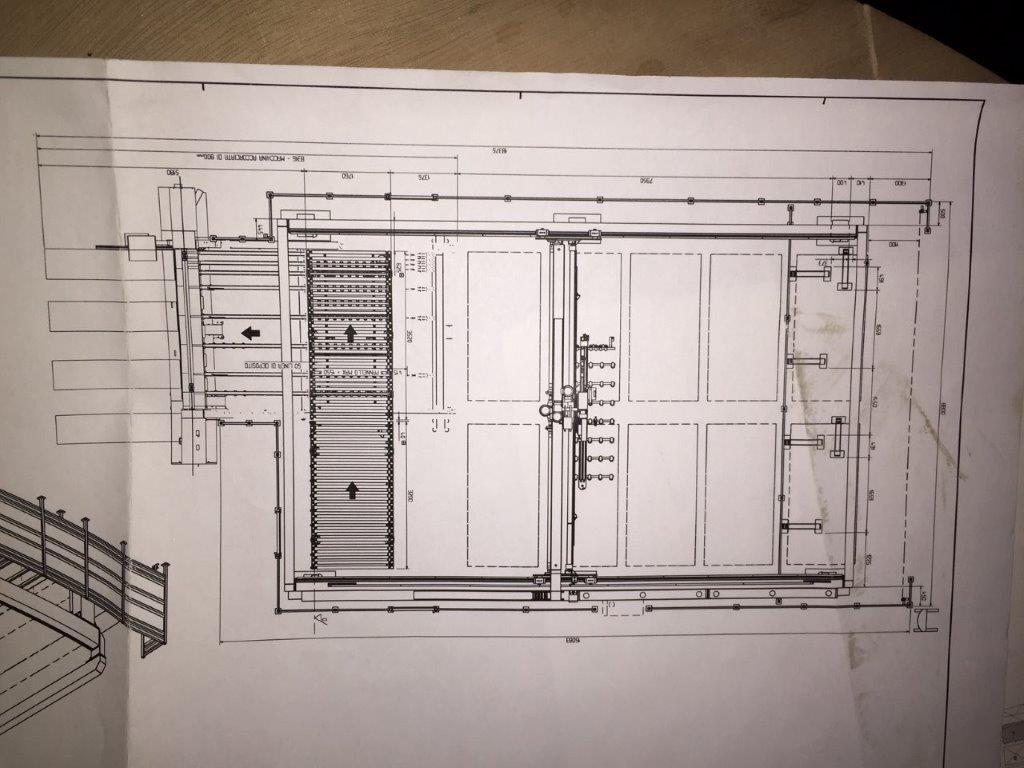

-Maximum panel dimension: 3200 x 1850

Blade protrusion: 105mm

Maximum main blade diameter: 380mm

-Main blade motor: 20 HP - 15Kw

- Main blade speed: 3900

-The blade diameter: 160mm

- Blade motor power: 2HP - 1.5Kw

- Remote adjustment of the saw from the controller

-Scoring Controller blade exclusion

-Transmission: rack on THK guides

-The transport cart advancing 1-150m / m

-Return carriage return 150m / m

-Pusher advancing 1-25 m / m (factory set at 25 m / m maximum for safety standards)

Return speed of the pusher: 90 m / min

-Motor pusher: brushless

-Number of clamp: 7

-Air speed: 35 m / sec

-Suction openings: 2x 120mm diameter, 1x 150mm diameter

- Sampling requirement: 4500 m3 / h

- Compressed air: 1/4 ″ ID

-Air consumption: 300 Nl / min

-Pressure: 7 bar

- Optimized stroke of the blade and pressure beam

-Electronic marker adjustment

- Cross sections for double-sided aligner - optimized stroke 2200mm

-Four (4) air cushion tables - 2500x600mm

Label printing is enabled in the controller and the label printer is included.

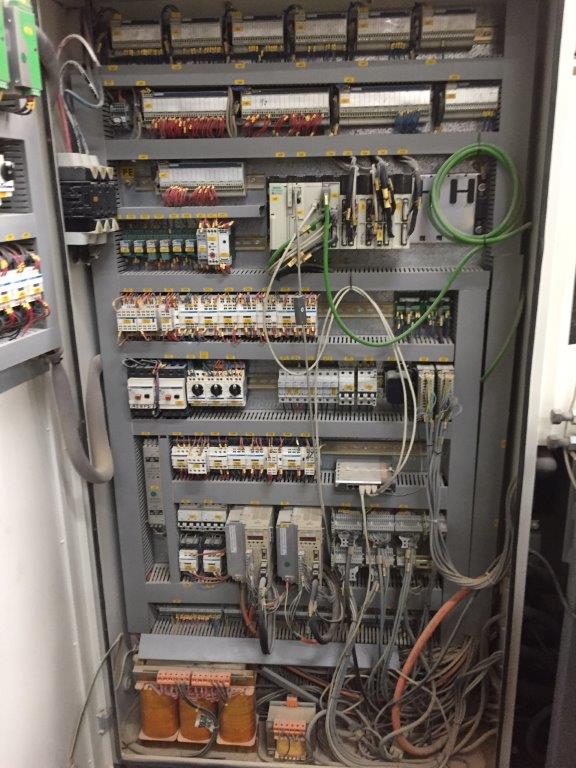

-PC Pentium Controller on current Windows

-Ottimo Top control software

Easy Cabinet software

-Telesolve to facilitate remote diagnostic evaluation

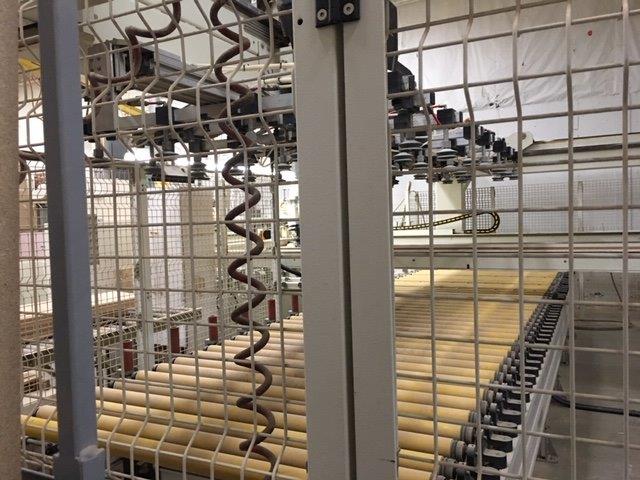

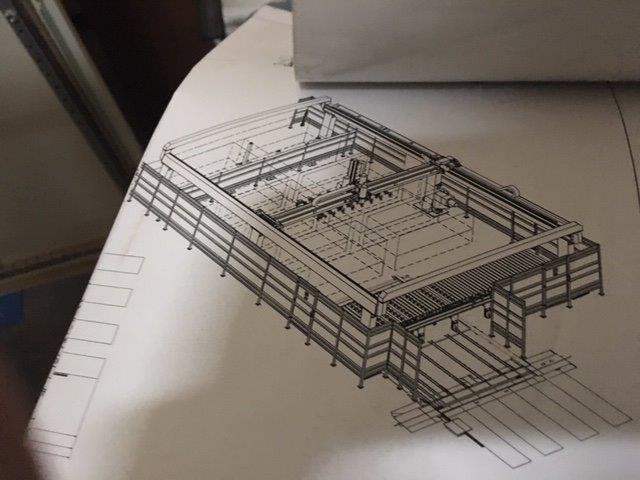

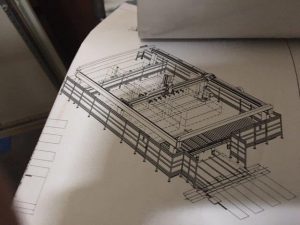

Mahros Runner 3 Assi 8 storage and retrieval system

-RUNNER suspended gantry loader made up of two gantry cranes which support the horizontal trolley with the vertical arm with suction cup. The system is designed to have two entry drop stations for new batteries, eight storage stations and one power station for the panel saw. The machine is fully automatic and does not require any manual adjustment. The horizontal movement of the carriage and the vertical movement of the arm are made with prismatic guides with recirculating spheres with automatic lubrication. These movements are given by timing belts and motors driven by an inverter. The suction cup holder frame for handling the panels consists of eight crossbars, each with 4 suction cups. The PLC, equipped with a keyboard and a programming display, controls the work cycle and provides the interpolation of the axes to shorten the path of the arms. A computer located near the two power stations allows the operator to manage the feeding of new boards from the two power stations to the eight storage stations.