New machines

Latest arrivals

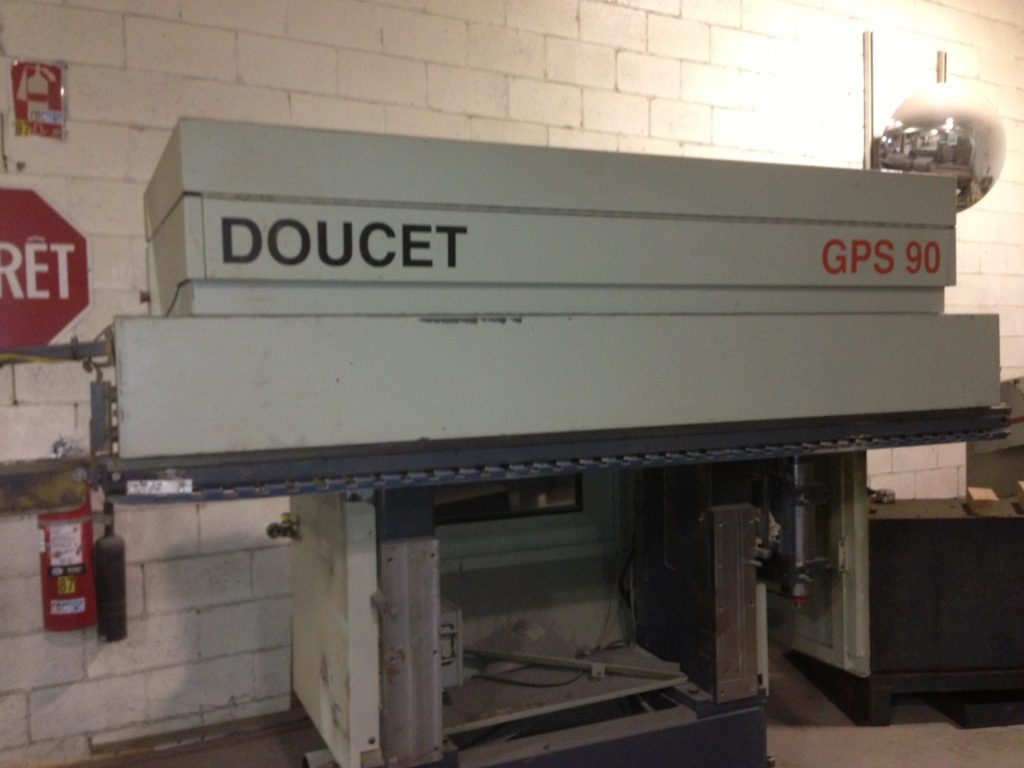

Used machines

- Sharpening

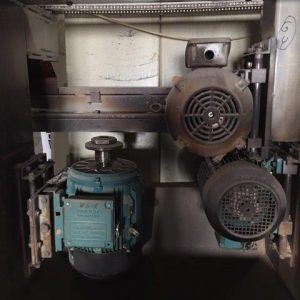

- Air Com / Dust Collectors / Motor

- Residue skip

- Bouveteuses - End-matcher

- Shred, Shred & Recycle

- Return loaders & conveyors

- Forklifts

- CNC

- CNC - 5-Axis

- CNC to Pods

- CNC Full table (Nesting)

- Conveyors & Trolleys

- Routers

- Jointer

- Multiple Rip Saw

- End Matchers

- Gluing equipment

- Sawmill equipment

- Window /Corner Cleaner

- Finishing - Air M-Up & Paint chambers

- Finishing - Complete lines

- Finishing - Dryers & Ovens

- Finishing - Varnishing

- Gougeonneuse

- Jointers

- Lamination - Packaging & Rolls

- Lamination & Gluing

- Ignition wood packaging cutting line

- Dovetail Machines / Drawers

- Handling & Automation

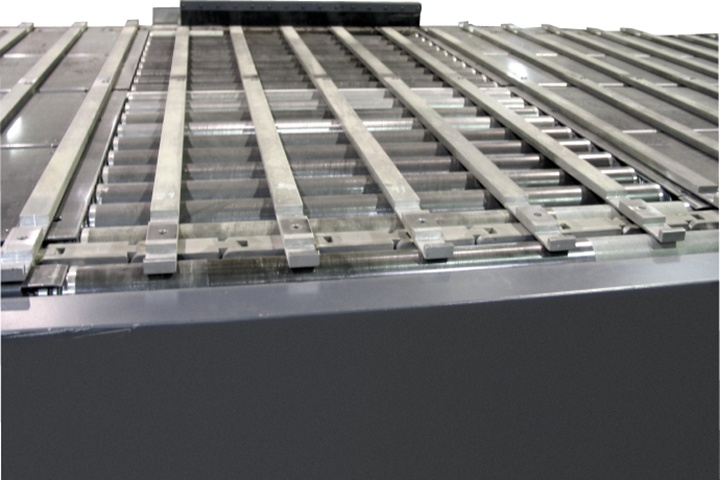

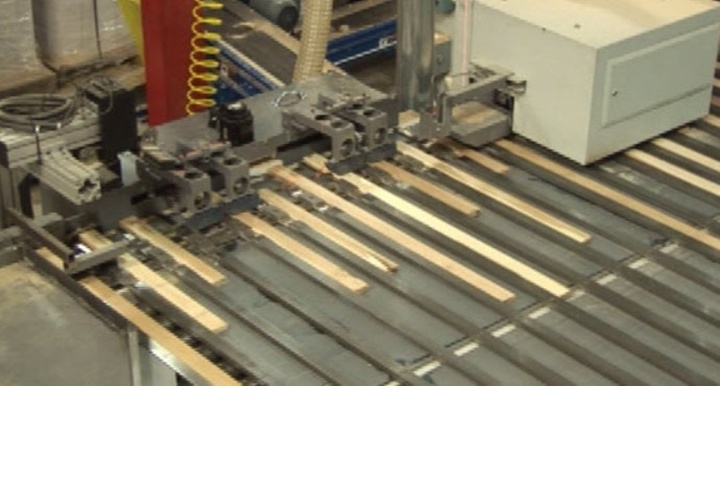

- Automatic handling

- Moulders

- Drills

- Plating - Couplers / Jointers

- Planers

- Edge banders

- Presses - Doors / Frames & others

- Presses & Clamps Carriers

- Sandblasting - Disc / Contour

- Sandblasting - Multi-head

- Sandblasting & Finishing

- Sandblaster -Molding

- Panel saw - Beam Saw

- Band saw

- Saws

- Saws - Vertical panels

- Portable saws & others

- Dryers, Burners & Containers

- Rotary Clamp Carriers

- Tenoners / Mortiser

- Spinning top - Single & Double - Shaper

- Wood lathes

- Uncategorized